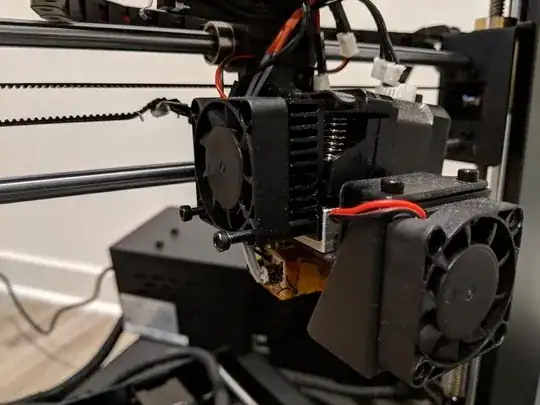

Printer: Monoprice Select V2.

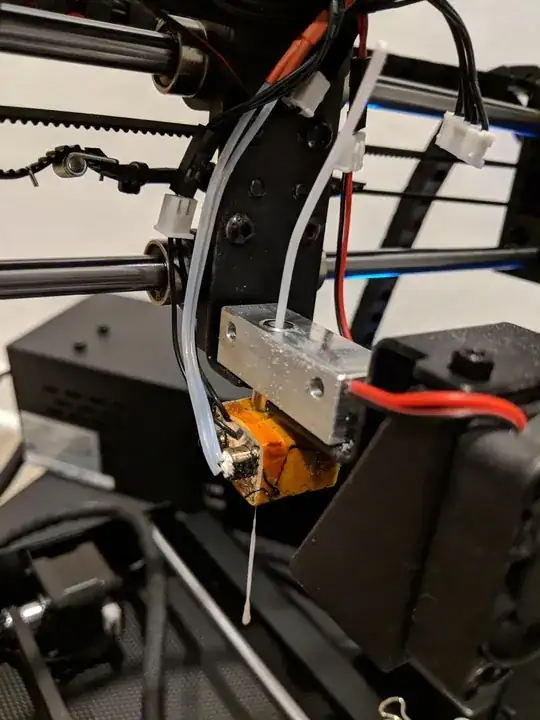

I've done several prints already and swapped out filaments many times but in my most recent swap, I can't feed my PLA through any more.

I first preheat my extruder for PLA temps (185 °C). Then I press the plastic thingy to allow me to push as much of the filament into the hole as possible. Then I adjust my extruder position to try to suck it in. Usually after a few mm, I start to see the filament come out of the extruder and I also feel a pull on the filament from the top. But nothing is happening now.

However, if I adjust the extruder position in the opposite direction, it eventually pushes the filament back up and out, so I guess the "stepper motor" (is that what it's called?) is working (at least in one direction).

I'm getting ready to open the extruder module up to see what's going on, but wanted to see if anyone had any simple ideas for me to try before I unscrew anything.