Here are the details of my printer:

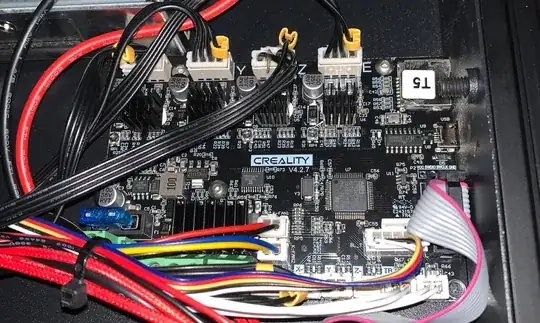

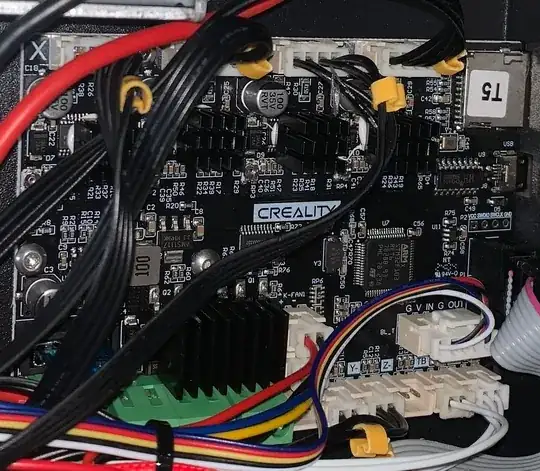

- Creality Ender 5

- STM32F103RET6

- CR Touch: - Model: ALT04 - CX: 231120001838

- Mainboard: v4.2.7

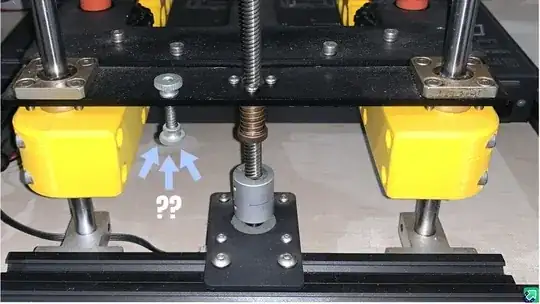

I’m trying to adjust the nozzle height on my Creality Ender 5 (4.2.7 + CR Touch) to -0.2 mm, so that it’s closer to the bed and the filament adheres properly. However, I haven’t been able to achieve this. I’ve tried several firmwares, both from Creality and compiled from YouTube tutorials, but nothing has worked. Additionally, I haven’t found any specific tutorials for my printer; I’ve only found versions for the Ender 5 PRO and Ender 5 PLUS, but mine is the standard Ender 5. Some people say that the Ender 5 PRO is nearly identical, just with better construction materials, so I’ve also tried several firmwares for that version, but still no success.

Here are the steps I’ve tried:

- Perform an Auto Home.

- Run

G1 Z0to check the current position. Normally, it should be X0 Y0 Z0, but I change the Z to Z-0.2, then save it withM500or through the printer’s screen to store it in the EPROM. - To apply this adjustment permanently, I configure

M851 Z-0.2, save it, and verify it withM503. Everything seems fine up to this point. I’ve even stopped the printer and reloaded the configuration from the EPROM, which keeps the changes. When I runG1 Z0again, the nozzle moves to -0.2. However, when I start printing, the nozzle returns to the default position. - I’ve also tried leveling the bed using Bed Leveling, creating a mesh to apply height adjustments during printing and saving the settings.

- When the nozzle is still too high during printing, I’ve tried using the BabyStep Z feature, but it doesn’t seem to work.

Current config file: https://github.com/viikktorr/ENDERv5