I had a problem with ASA part warping and not sticking to the build plate as shown by this question and answer

Issue stem from under extrusion of the first layer and was solved by bumping first layer flow rate from 100 % to 120 %.

I am wondering, how does one differentiate between first layer flow rate being too low or global Z nozzle distance from plate being too large for the whole print? I've seem comments that adjusting first layer flow is just a hack and it does not address the original problem - whatever that may be.

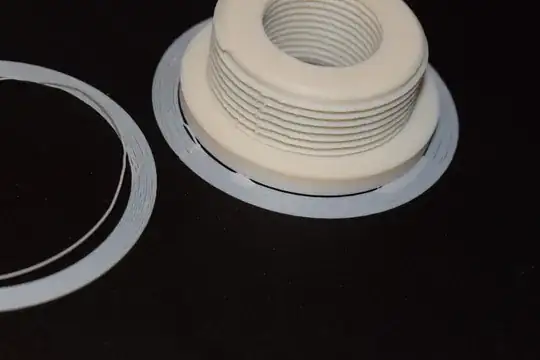

Before initial layer flow rate increased:

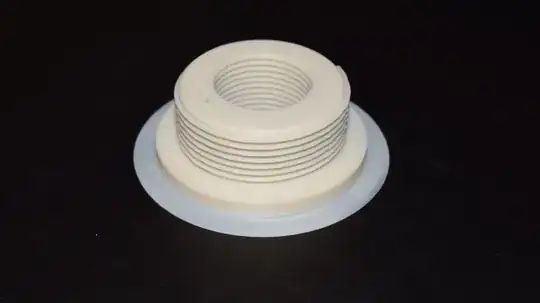

After initial layer flow rate increased to 120 %: