I am having first layer adhesion to the build surface and warping problems when printing ASA.

- I am printing in enclosed printer,

- build surface is heated to 85 °C 15 min before prinitng (and to 110 °C when printing),

- the bed was cleaned with isopropanol and sprayed with 3DLAC on the preheated bed right before hitting print,

- printer has bed autoleveling and it is done before each print,

- I've added lots of brim lines,

- nozzle T is 255 °C and print bed T is 110 °C, no cooling fans, other settings are Idea Maker's default apart from 75 % infill density, 30 % infill overlap and 0.21 mm layer height.

I am not sure what else could I do in terms of controlling environment.

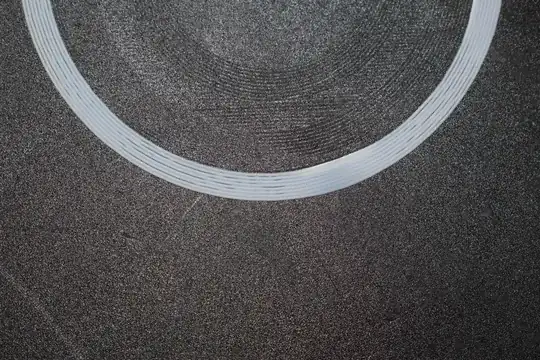

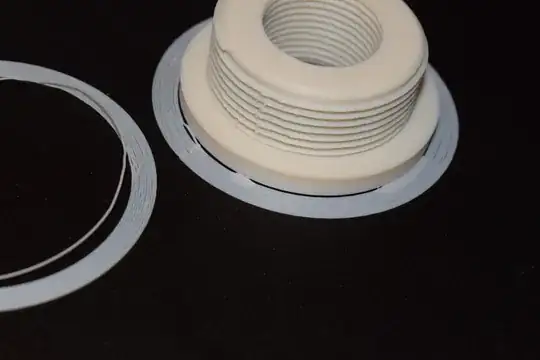

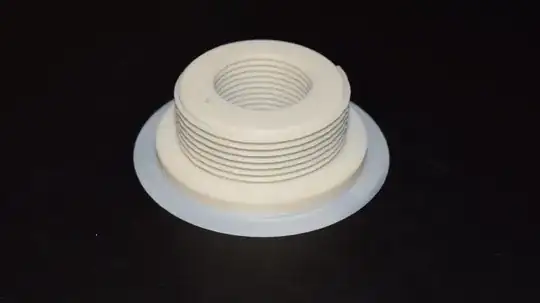

Here are some images of the print. I noticed that the first layer has gaps between filament lines. Moreover, brim is mostly not even touching the part. I think this is largely an issue with the first layer only. The parts in images were left in the printer for 1.5 hour too cool down slowly and the OK looking one is still bottom warped. I am suspecting my warping issues are due to under extrusion of the first layer. What do you recommend I try next? Printed on Raise 3D E2 on factory BuildTak build plate and sliced with Idea Maker.

My first layer flowrate is 100 % and first layer extrusion width is set to 130 %.