I just upgraded an original CR-10 with the CRTouch bed leveling sensor and upgraded the firmware from stock to Marlin. In the CURA slicer, I added a preamble to every print to perform bed leveling. The bed leveling is running a 5 by 5 (25 point) leveling sequence. The sequence is not started until the bed and hot end are at temperature.

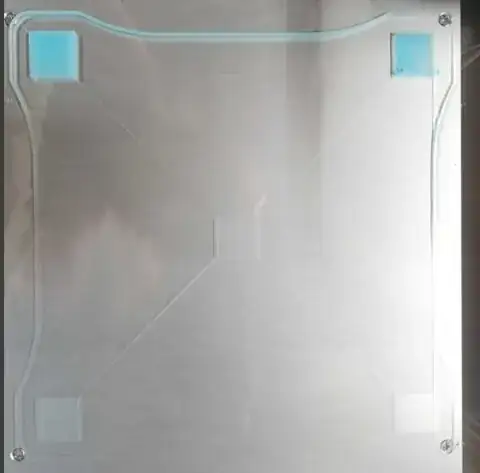

When using the above configuration with a bed level test (5 squares, 1 in each corner and at the center of the bed) the squares on the right top and right bottom printed so thin I could see through them!

(In this image the top is the left side of the bed and the bottom is the right.)

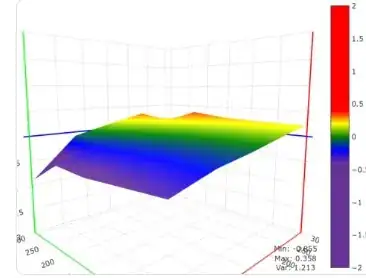

I then used OctoPrint to report on the bed height and found that the left side of the bed was about -0.5 mm and the right about +0.5 mm.

Is it incorrect for me to assume that bed leveling could have compensated for a 1.0 mm difference between the lowest and highest points on a 3D printer's bed??

To verify that all the software and hardware were actually performing (some) bed leveling, I observed the Z-axis stepping motor while printing the skirt for the above bed-level test pattern. I did see where the Z-axis stepping motor turned about 1/4 of a turn in the positive (up) Z-axis direction as the hot end traveled from the (low) left to the (high) right side of the bed. So, bed leveling appears to be working. But not enough to make a good first-layer print on the right side of the bed.

Added later...

I needed to add to the question to address manual bed leveling. As asked by a 3dprinting.stackexchange.com contributor.

This is not a question regarding manual bed leveling. This is a question asking how much can auto bed leveling compensate for. Specifically, can a 25 point scan (a 5 by 5 point grid) before every print compensate for 1 mm linear (not a dip but a straight flat surface) difference from the left side to the right side of the glass build surface.

Before posting this question, in a effort to fully understand the situation, I did verify the CR-10 printer could pass the bed leveling test. I did this by reverting to manually leveling the bed before the second bed leveling test. I did this (manual bed leveling) just as if no CRTouch was installed. Just like I would have over the previous 6 years using this printer and glass bed. The results were great. Please note what I am inferring here ... in order to pass the bed level test, I had to manually bed level the CR-10. The CRTouch did not make any difference. The first test failed despite using a CRTouch and 25 point alignment. And the second test would have likely passed with out using the CRTouch after the bed was manually leveled.