I have an idea for a 3D printed project, but I'm a total noob in this area and need someone to reality check it for me.

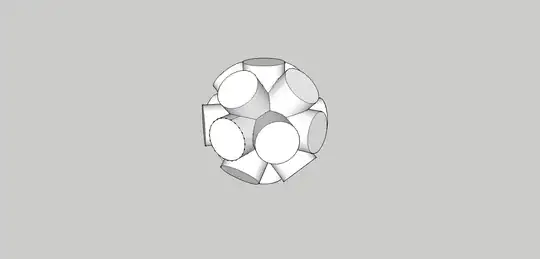

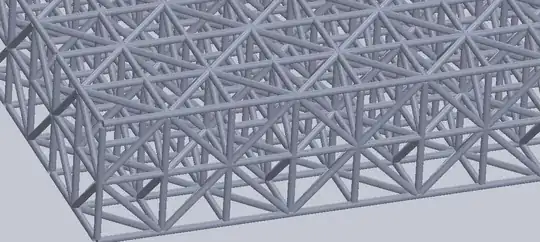

Basically what I want to do is a tricopter frame made of a tetrahedral honeycomb.

The whole model would be within 30 * 30 * 10 cm, the honeycomb edges would be approximately 1mm thick and about 15mm long and it would be printed out of nylon with SLS.

I have found Shapeways' design guidelines and my idea seems to fit it, but still it feels slightly more extreme use than what they had in mind.

Is this doable? Does anyone else use a similar method? Is there some software that I can use to generate honeycombs like this, or do I have to write it myself?

Edit:

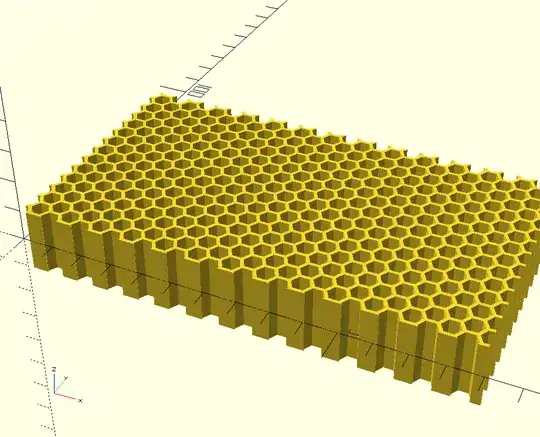

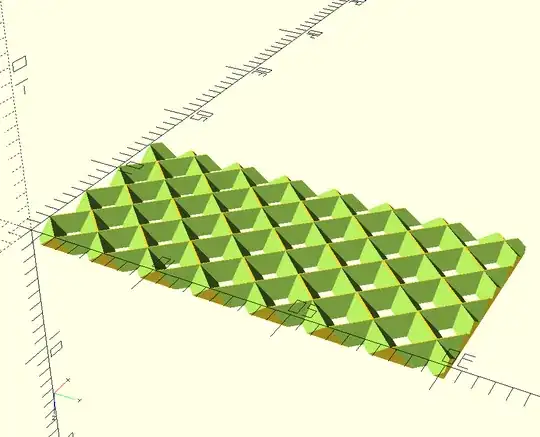

This is how two layers of the honeycomb look like:

In the actual model there would be several layer of this on top of each other and the shape would be kind of carved out of the honeycomb (+ some finishing to avoid spiky surface)