I’m using a RepRap printer, PLA (Hatchbox 1.75 mm), SketchUp, and Slic3r. The heated bed is covered with a blue polyester sticker. When I print small holes (1 to 1.5 mm radius), slicer software considers the holes outside edges for the first layer and prints them before the internal first layer. The problem is, unlike the actual outer edges, the holes have no brim and the small first layer circles stick to the extruder rather than the bed. The rest of the first layer print sticks and the print eventually recovers with slight defects depending on where the lifted circles end up. If I could print the first layer circles after the surrounding first layer was printed, this wouldn’t be an issue. I’ve tried different bed and extrusion temperatures. All four holes in different locations do the same. First layer is 0.3 mm thick. Second layer is 0.2 mm thick.

4 Answers

I would use a very slow print speed for the first layer, something like 20mm/s or less.

This will make your first layer so slow you will be tempted to bite the steel rods.

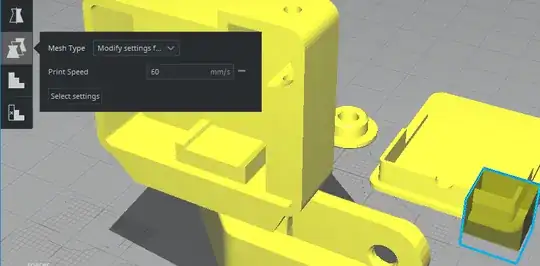

If you were using Cura (I don’t know if Slic3r has a similar feature) you can change this parameter only for those areas where you have these small holes: with the Custom Supports plugin you can specify a different print speed for a specific area

- 337

- 1

- 10

are you using hairspray or tape to help with bed adhesion? If not that might help.

Also try printing the first layer slower or try adjusting the bed level offset so you are squishing the first layer down a bit more.

- 161

- 1

Print at 5% of the print speed, and ramp up cooling to 100%. This should give the plastic time to shrink and adhere to the bed. If not then use a raft.

- 2,488

- 12

- 21

You didn't say what type of bed you have, but I'm guessing glass. Do you have a BuildTak or comparable generic surface you could clip on and use? I've never had adhesion problems like this with my Ender 3, which came with a BuildTak clone; PLA just sticks, with no brim, no glue, no hairspray, etc.

- 13,474

- 5

- 43

- 79