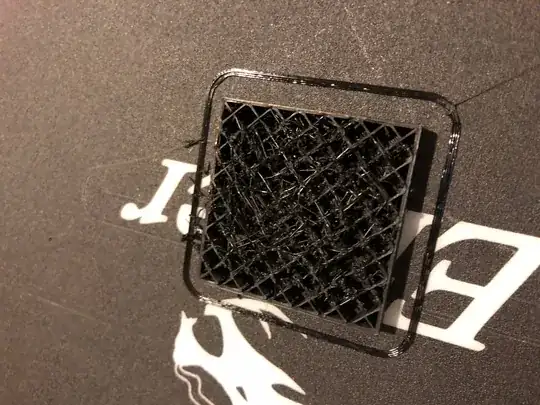

I'm new to 3D printing an I just got a Creality Ender 3 and I think I'm getting some good results with small prints. However, now that I'm trying some bigger prints and I'm running into infill material excess. In the picture below I just printed a solid cube with 20 % infill and that's the result.

I have been playing with settings a lot but I'm really running out of ideas.

These are the settings I have:

I have been playing with settings a lot but I'm really running out of ideas.

These are the settings I have:

- my bed, fortunately, came in pretty flat. My first layer is always very good indeed

- bed level method: paper method

- Slicer: Ultimaker Cura

- material: PETG (Amazon basics)

- layer height: 0.2 mm

- nozzle temperature: 230 °C, but also tried 220 °C and 210 °C

- bed temperature: 90 °C

- flow: 98 %, but also tried all the way to 90 %

- cooling: 0 %; the issue got a lot better with some additional cooling but I see a lot of people printing with no cooling

- infill density: 20 %

- retraction: on, 5 mm

- retraction speed: 40 mm/s

- first layer print speed: 30 mm

- print speed: 50 mm/s

- wall speed: 50 mm/s

- infill speed: 50 mm/s

Let me know if you want to know more settings, but I think these capture most of it.

If you guys have any suggestion on things I can try that would be of great help.

UPDATE

After playing with some settings these are the changes I think I'm settling on:

Flow: 105 %

Coasting: On, 75 %

Cooling: 60 %

Retraction speed: 50 mm/s

Here is a picture of when the infill issue starts:

NEW ISSUE

Now I'm getting a lot of stringing. Actually, I don't even know if it's stringing since I ran a test and came out basically perfect. Not a single stringing.

I'm getting a lot of material that get dragged when the nozzle moves to one place to another and a lot of material accumulates on the nozzle and slowly drips everywhere during the print.

Here is a video I made (not sure if it helps at all)

Here is a video I made (not sure if it helps at all)

https://www.youtube.com/watch?v=tlIB1WW8z84&feature=youtu.be

I think I'm getting close to have good prints but I really can't figure this out.