My i3 MK3 is printing very well for solid parts of an object, but it messes up with infill.

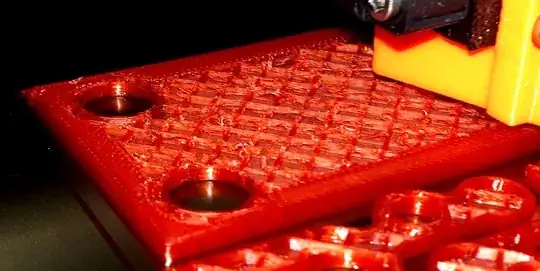

As you can see in the image, the infill is broken into pieces and bends to that the surface becomes rough and the nozzle touches it next time it moves there, which probably does not make things better.

I've read the Prusa problem page, where they suggest three solutions:

- change infill type

- flexible filament (I'm using PETG, so this does not apply)

- lower printing speed

I'm printing with 20% infill and I believe that this worked before at the same speed, so I'm tempted to say that both remaining options are options, but it should work without them.

It also seems to me as if the infill is thinner that ordinary walls. Is the extrusion speed lower in case of infill? Is there a way of changing the extrusion speed for infill?

Side note: my printer always tells me to upgrade to the latest firmware 3.5.1. Since I have just received the printer back from a warranty repair after the last firmware upgrade, I don't want to upgrade the firmware. Could the issue be related to firmware?

Infos requested from comments:

I'm basically using the Slic3r default settings for PETG. The only thing I adjusted is the temperature, since I'm using HDGlass PETG and there was a recommended temperature written on the spool. Relevant settings seem to be

- Filament settings

- fan speed min 30 % max 50 %

- bridges fan speed 50 %

- enable fan below 20 s

- slow down below 20 s

- min print speed 15 mm/s

- Speed settings

- Perimenters 45 mm/s

- Small perimeters 25 mm/s

- External perimeters 35 mm/s

- Infill 200 mm/s

- Solid infill 200 mm/s

- Top solid infill 50 mm/s