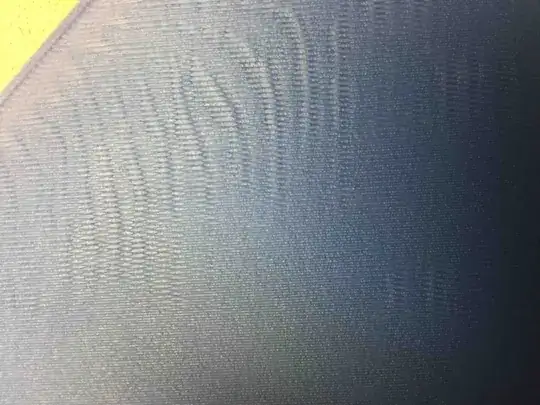

I'm having issues with ripples on the first layer of big flat prints. The initial corner of a big flat print is fine, but then ripples begin to form as shown in the screenshot.

I'm just a newbie, so I was thinking they might have something to do with heat or contraction or something. Normally, I use the default and print with no turbofan on the first layer. When I tried adding fan 20% or 50%, nothing much changed (slight differences in the ripple pattern and area, but that pattern varies anyway).

I also wonder if one strip gets bent, then maybe the rest just follow the bends. As far as I know, my heating plate is working fine, has no serious hot spots, and I'm using a high-quality PLA+ filament. I also tried adjusting the print temperature from 205-220 (the range on the box is 205-230). Nothing seemed to help. I am running a default first layer thickness of 0.3 mm because that is supposed to help adhesion (and adhesion is fine).

The ripples look worse than they feel. They feel fairly flat, only slightly rippled, even though they look terrible! (And I don't know what that weird row with blobs is in the top left of the picture. That only happened once; almost like junk was in the nozzle or the feed gears slipped or something).

I'm running a Qidi Xpro machine, Sunlu PLA+ (wonderful) filaments, bed 50 C, print temp 205-215, print speed 30-40 mm/s on the first layer, and first layer thickness 0.3 mm (normal layer thickness is 0.2 mm). This machine has a direct drive with gears immediately above the nozzle.

Does anyone know why this rippling effect occurs, and what I might to do to correct it? Thanks

UPDATE: I'm adding this info here to respond to several comments concerning bed leveling, etc. (Thank you to those who made comments!)

1) I'm sure that the bed is as level as I can make it because I always go through the cycle twice).

2) Regarding clearance, if anything I worry that my clearance is too small since there is a fair amount of drag on my leveling card under the nozzle. So, there is definitely drag on all three level points, about midrange between the lightest drag and the heaviest drag that makes me think I'm filing off part of the nozzle.

3) I do have two nozzles, so I suppose the problem could show up on one but not the other if the nozzles were screwed into the block to give different heights. But the ripple shows up on both nozzles, always in the middle of the build plate, always in the middle of a big flat print. Corners don't usually show ripple effects. I don't want to believe that my build plate dips in the middle on my new machine, either ... :-) Adhesion is fine on small prints in the middle of the plate.

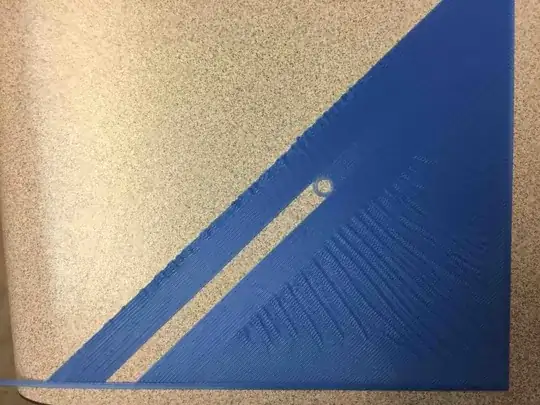

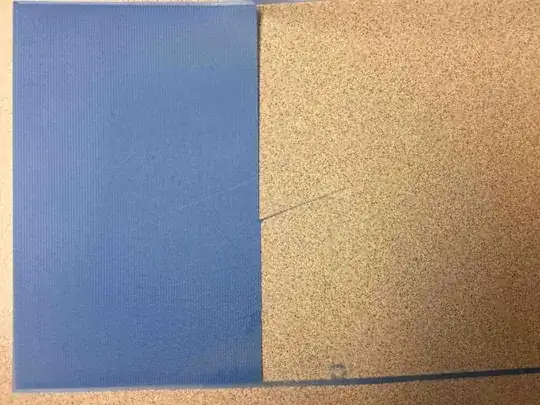

Here is a picture of the bottom of the piece. A careful examination shows an oscillation in the squished filament segments on a filament thread. Almost like the extruder was oscillating vertically in the z-axis at that frequency, or perhaps the filament squishyness was oscillating at that frequency. Looks almost like a weave pattern, since the squished parts alternate position on alternating lines.

It's worth saying again that the piece feels pretty smooth on both the top and bottom sides, even though it looks awful. I don't know what to make of that.