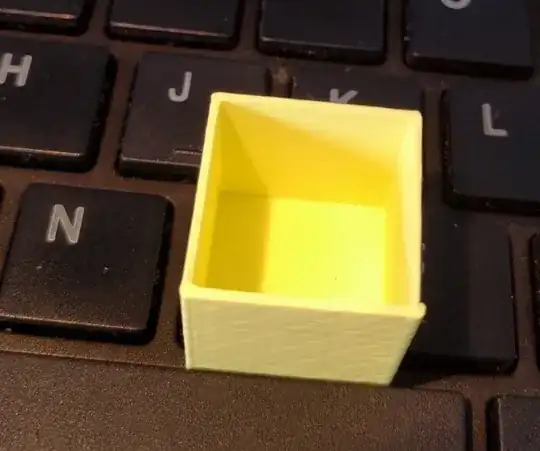

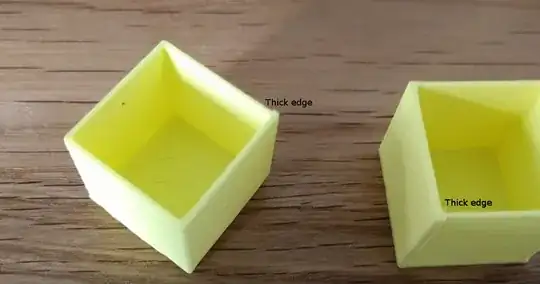

I noticed that one edge (which is also the starting point of the print) is always bigger than the other three. Additionally, the walls do not have the same thickness as well. The wall thickness (starting from the thick edge) starts very thin and gets thicker till reaching the thick edge again. Does anyone have a clue whats the issue?

Asked

Active

Viewed 2,510 times

2 Answers

3

As Fernando suggests, the problem is likely with your source file. One easy way to verify this is to slice twice, rotating the STL by 90 degrees. If both prints produce fat/thin sides in the same dimension on the print bed, then it's a printer problem. If the fat side rotated with the STL orientation, then the STL is at fault.

Carl Witthoft

- 3,073

- 1

- 12

- 18

1

This happens when you have poor retraction / oozing.

Signs of too high temp and poor retraction

- Thick blob at start point, meaning moltin plastic is oozing out as you change Z position

- As you see at the end of the line less material, you prematurely oozed out liquid plastic. As the melt zone is depeleated you get thinner lines.

Solutions

- Increase retraction distance. This will remove the plastic from the melt zone and prevent some of the oozing.

- Speed up Z axis lower and raising. Or decrease distances

- Lower temps. Start with 3 cel increments. You want to go as low as you can without causing print defects.

You will likely need to do 1 and 3. 2 you really shouldn't need after you fix your temps.

JJJ

- 3,133

- 3

- 15

- 29