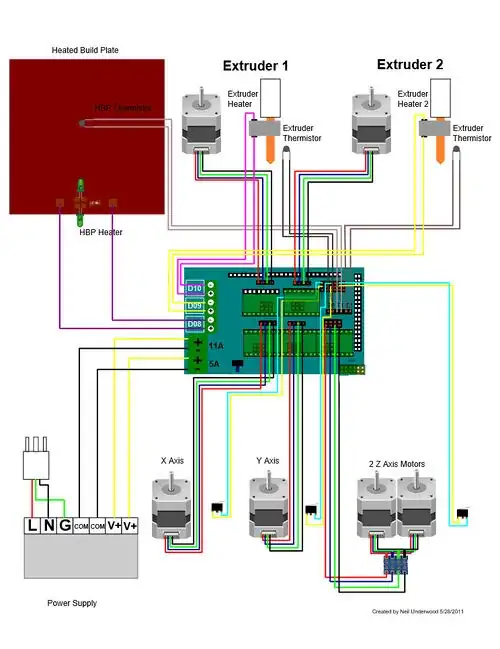

Currently I am using a 12 volts, 20 amperes power supply (Model S-240-12)

The stepper motors and the extruder need 5 amp, and the heated bed build plate needs 11 amp.

Technically you only need to use a 12 Volts, 16 amperes power supply, but I understand that you use the one with 20 amp because pulse currents from extruders and stepper motors can be stressful to supplies loaded to the max, so for reliability and performance, it is better to use a supply rated for 25% more than you need

In the place where I buy the spare parts for my 3d printer they also sell 12 V power supplies capable of delivering 25 amp and 30 amp and they told me that if I use those ones you are going to be able to speed up the heating of the heated bed. Is that true? I understand that the heated bed is only going to take the 11 amp that it needs so is not going to make any difference to use power supplies capable of delivering more current