I have looked into this a lot. Especially when I had a phd chem engineer girlfriend who kept talking about how the fumes might give me cancer.. Frankly the system you need just costs too much. Lab equipment can run 20k easily. Not to mention the noise. What you really need is a backyard shed, but as one who lives where it snows I understand that is rarely a realistic option.

The Buzzbox looks cool and there are other brands. However their prices are usually as much as a flashforge, and usually cannot even hold a flashforge.

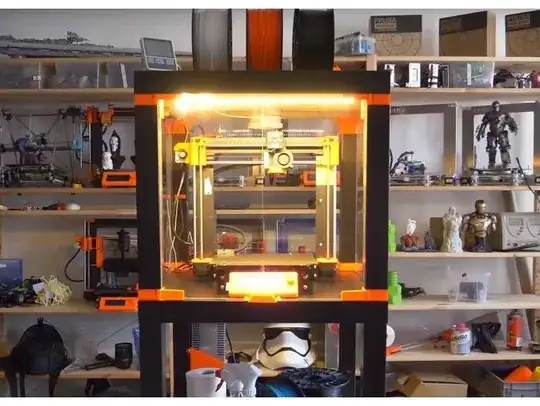

More importantly there are parts where you can DIY your own.

300 for a plexiglass case that can only hold a mini printer is not good enough by far.

Take a product like this air scrubber Or build your own this like this hard core one designed for a laser cutter.

The local hackerspace should have a large laser cutter. Plastic should run 100 - 200 depending on how thick of a sheet you want. I personally buy scrap pieces. Designing a square box, adding hinges, then coating the edges with silicon sealant. Evacuate the chamber when done printing. Also should double as a heat chamber..

For me, I can easily run 5 printers at a time. So I might take a metal Cabinet, seal it up. test it with a fog machine. Cut out a hole for the evacuation hose, and wire up camera. But I am far from having that much free time.

Also if I manage to make it air tight it should reduce fire hazard.

Taking that laser cutting fume extractor. There is nothing that will perform better than that. I hear you might get some smell, but that was in regards to laser cutters.