I recently got started in 3D printing but here's an issue I can't seem to find a solution for (I don't know what exactly to look for).

Here's what I did:

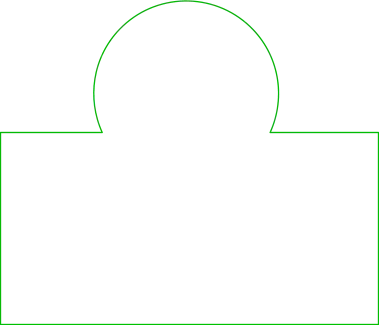

- I used InkScape to convert an emoji in to a svg and imported it in to Blender

- Used the Solidify modifier to make the curve a solid and converted it in to a mesh

- Extruded the mesh a bit, fixed a few non-manifold vertices and erroneous faces and saved the whole shebang as STL

- Imported the STL in to my printers software:

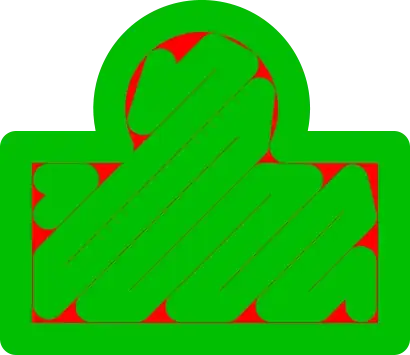

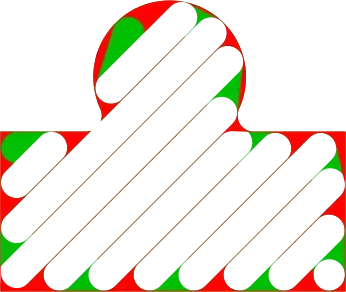

- After slicing it looks like this:

Is the software making a mistake during the slicing? Or is my mesh screwed up?

I have a FlashForge Finder and using the software that came with it: FlashPrint.

Edit: I uploaded everything to Thingiverse for those who are interested.