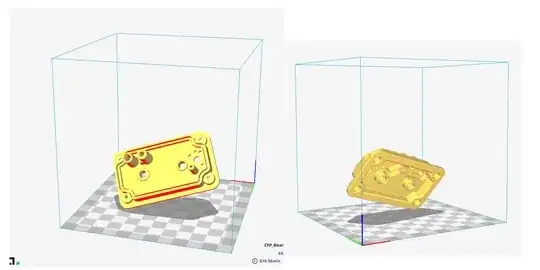

You can print it laying flat on the bed with supports. It will be very laborious to clean up, but it will probably work. supports usually are thin enough to strip away, but they leave marks which you need to cut off to get a clean result.

You can also buy a printer with dual extruders and then use dissolvable supports. That would probably be easier to clean up and provide a cleaner result.

If you're using PLA to print, you might get away with turning up the part cooling fan to the maximum level and hope for the best. Overhangs are very much prone to dropping though. I'm not sure if a stock MP Select mini will get the job done. You might want to consider an upgrade to the part cooling fan. You can look for fan duct related upgrades which allow you to mount bigger fans on Thingiverse

With PETG you can possibly get away with longer overhangs, as it cools quicker. However, PETG is much harder to print well, as it's much more prone to stringing, which can cause issues like artifacts and clogging.

All in all I'd start out with getting a good benchy before you start on engineering projects. This will make sure that you have your printer calibrated to perform for your chosen filament. Every brand and type has their own quirks and differences, so you'll have to fine tune your settings to get the best result.

A CNC-like finish will not be easy to achieve. A CNC type finish will be unachievable without extensive post processing if you're using supports. In any case, getting a good finish requires some practice with finding the right settings for your filament.

Learn how to print and to get your printer dialled in to achieve the required result, which, in the case of it having to be CNC-like, is quite high-end. The fact you're laying down filament means that you'll be able to see lines, even at top quality. Maybe this guide will help you get on your way.

Getting a $1000 printer mainly inproves reliability of the print. The quality of the print is in the skill of dialling in the right settings in your slicer for a given filament choice, plus recognising the type of supports necessary. This takes practice to achieve.