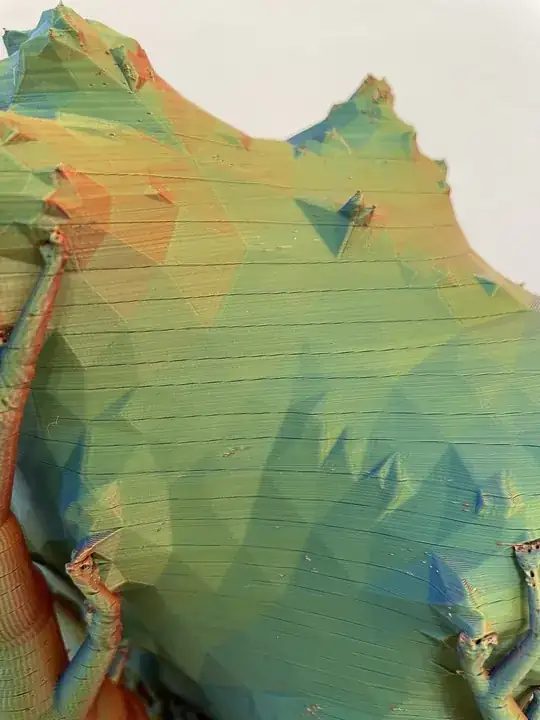

My print has a regular spiral underextrusion which crosses layers (see attached photo). It is likely not a slicer issue since multiple prints of the same model have the spiral pattern in different locations. In particular the underextrusion is not along the Z seam (which follows the sharpest edges in the model).

Elegoo Neptune 3 Pro, Ziro matte tri-color filament, 195 °C, very slow print speed.