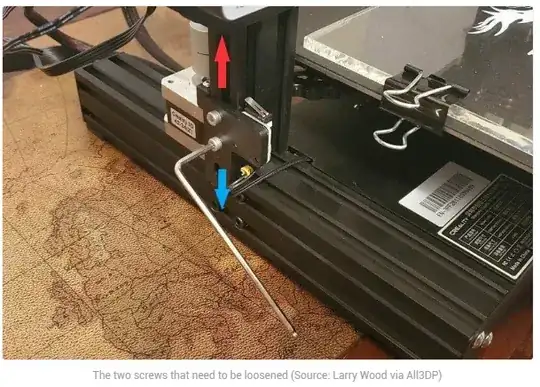

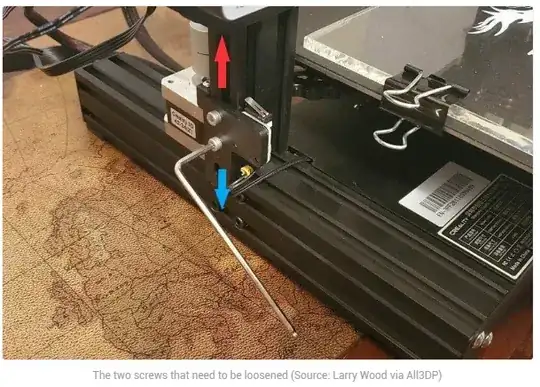

There is only one thing you can do if there are no more threads left on the levelling screws, you need to move the Z-end stop assembly (depicted in the front left of your photo) to a lower position. Just unscrew the two hex screws a little and move the assembly down (blue arrow direction in the bottom/last image below). However, the more recent Ender 3 versions have a notch on the Z-end stop bracket:

That notch rests on the frame:

You should not be lowering this notch lower than the aluminum frame top.

Referring to your image and enlarging it, it appears you still have some threads left (encircled in red), this may be enough to get the bed to the nozzle (note that the leveling screw contains a knurled brass M3 insert, so you should be able to unscrew a little further):

If not, you should first unscrew the levelling screws a little so that you can properly tram the bed (alternatively, use longer countersunk screws). A detailed description can be found at All3DP's Ender 3 (Pro) Z Offset: How to Adjust It.