These are (at least almost certainly) not layer shifts. A layer shift is when the physical toolhead position becomes inconsistent with the logical one because a stepper motor missed a step or the bed surface shifted or something else went wrong. It's possible for them to reverse if the same happens in the opposite direction at a later layer, but very unlikely.

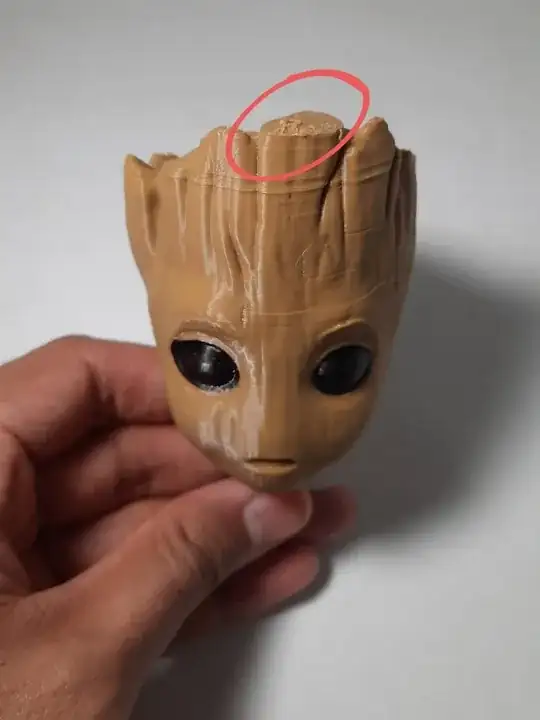

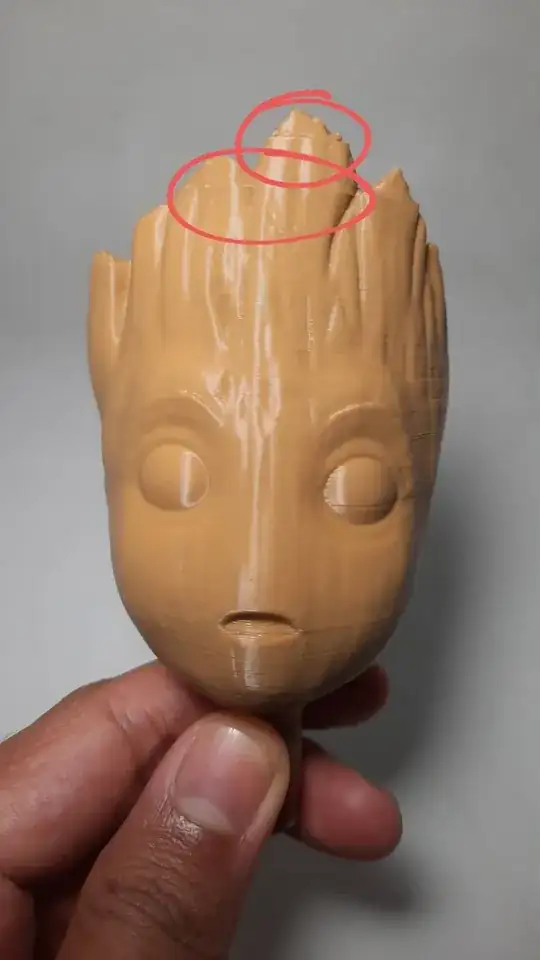

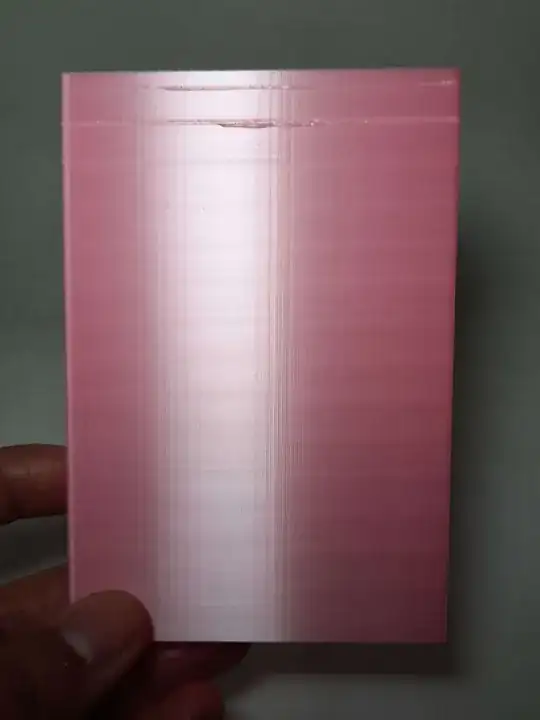

What you have seems to be geometry-dependent inconsistent extrusion. If you look at the slicer output in an analyzer, you probably have some geometry difference in terms of number of components, travel moves needed, etc. at the affected layers, causing more or less material to be oozed/lost in the model's interior, thereby producing more of less extrusion thickness in the walls that follow, relative to other layers.

While there are probably other ways to reduce the impact, the right way to fix this is find the cause of the oozing and stop it. It's almost surely unretracted travel moves inside the model interior, which Cura calls "combing"; I don't know the Prusaslicer terminology for it. You can either turn it off (which will make your print a lot slower and might harm quality in some ways) or set "Max Comb Distance With No Retract" to something very small, like 1 mm. This will create a lot of additional retractions, and you need to make sure your retraction settings are right (in terms of distance and speed) not to make the problem worse - you can also ooze material while waiting around for a slow retraction to happen. Doing a retraction tuning tower can help you get them right if you don't have them right already. On an Ender 3 you should be able to set the retraction (and unretraction) speed to at least 100 mm/s, with distance somewhere around 4.0-6.5.

For readers using Cura, also be sure to set the "Minimum Extrusion Distance Window" option to 0. Otherwise Cura will start skipping retractions again once there are too many of them, which will bring the problem right back, possibly far worse since it might skip them even in the places they matter most. I don't think Prusaslicer has such a problem but I'm not sure.