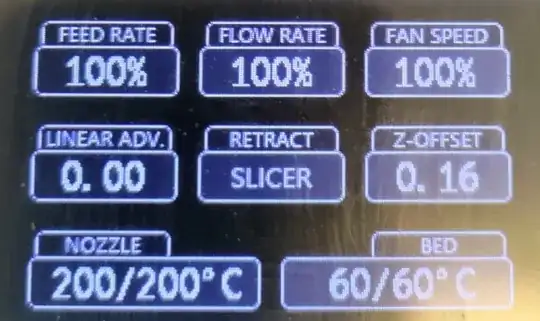

I recently received my Creality CR-6 SE printer and upgraded the controller board to a Bigtreetech SKR CR6 V1.0 and installed the latest community firmware.

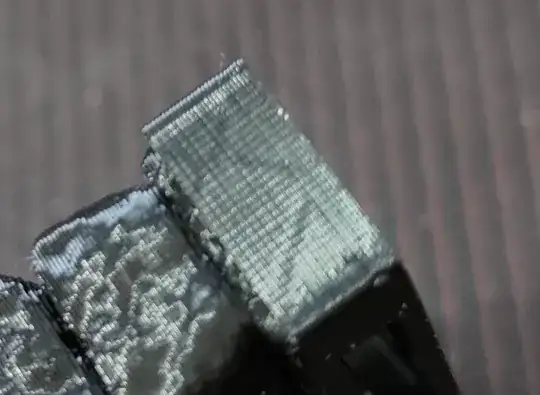

As you can see on the attached image, the corners have this weird elephant foot thing going on the vertical surfaces.

Then there is that zig-zag pattern across the flat surfaces on the sides, makes me think the cubic infill pattern is shining through the sides. I am using Cura 4.8.0 with a modified start G-code to put a purge line on the side before print to prevent drooping in the middle of the bed while probing for the Z0.

What causes these issues? I have not tweaked anything regarding the extruder aside from adjusting the screws that clamp the filament as the stock setting broke the filament when retracting because it clamped on too hard.

I have not changed the E-Steps, on the stock firmware this wasn't even possible.

I use Raise3d Premium PLA filament, I have tried a few and I'm most comfortable with this filament.

If this is over extrusion, I can totally work with that. I have done E-step calibration before on my Ender3. I will test for that after the current print is done.