We're thinking of buying a PETG-powered printer. When researching printers available on the market, there are machines with a 100 microns. I was wondering if there are machines with a 50 microns or close to 50 micros? Otherwise, why not?

2 Answers

I assume you mean a resolution of 50 microns (0.05 mm step size) Most FDM printers can produce something useful upto 100 microns. If you want to print with more precision, try resin printers. The reason for this is that an FDM printer uses an extruder with a specific nozzle diameter (typically around 0.4mm and minimum around 0.25 mm). plastic has too much viscosity to fit through a smaller diameter nozzle easy.

PETG is a material type that is only available for Fused Deposition Modeling (FDM) type printers. Those are limited in their achievable resolution by their nozzle size:

- the Smallest depression in a surface that is printable is about half a line width in XY and 1 layer height in Z.

- the smallest bulge from a flat surface that can reliably be produced by FDM is in the area of one line width in XY and 1 layer height in Z.

- The minimum thickness of an item to be printable is one line width.

- The maximum layer height in Z is 3/4 of the nozzle width.

- Optimal line width is 1.1 Nozzle diameters.

- That all is the theoretical limit, as machine movements and such push this minimum up by a factor of at least 1.5 and more likely 2-3, depending on how much your machine is tuned.

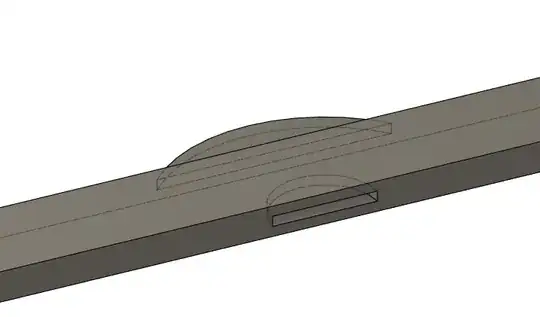

The smallest available nozzles that doesn't require specialty extruders are 0.2 mm. That means the absolute minimum detail that could in theory be reproduced on a surface of enough thickness is a 0.1 mm depression using a design similar to this picture:

As a result: NO FDM with PETG is not a solution to your requirements, you want reliable 0.05 mm resolution in XYZ, which is the area of Resin printers, especially DLP and SLA, but also Stratasys PolyJet can achieve this at the moment.

Estimating from your other questions (like this), I still suggest looking at a resin-based system that has materials that are certified for medical use!

- 22,760

- 13

- 53

- 106