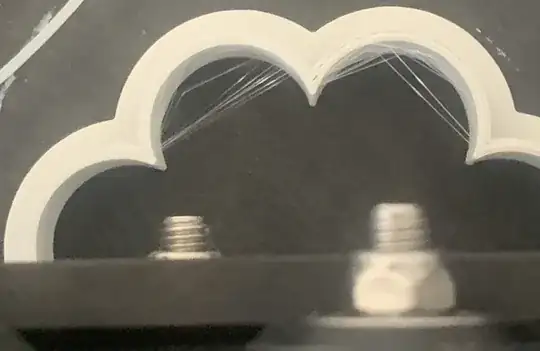

These artifacts can be either moisture, as explored by this answer or problems with temperature/speed control or the Z-Axis:

If the temperature is not hot enough, the filament might not get melted enough to squish down to the next layer nicely at the speed the head moves at, resulting in the cooling filament getting dragged behind the printhead and forming a line in the air. Due to such errors I generally tend to print PLA more in the upper temperatures than where it barely liquifies.

This also can happen if the printhead is not on the right Z-height and the gap is larger than expected. Usually, this happens only at the lowest layer when you are unlevel (bad bed adhesion is the result), but if you bump the printer or it hooks on something, during Z-travel, it can result in such a mechanical problem. Other reasons that show the same pattern are uneven Z-Axis movement. For example, a loose gantry or a defective Z-rod can lead to it, as could bad firmware or a worn-out motor that lost a coil or two.