Ender3 v2, SIENOC PETG which advises temperature of 230-250 °C on the box. I'm printing on top of cleaned blue tape, using a temperature of 230 °C for the nozzle and 80 °C for the bed.

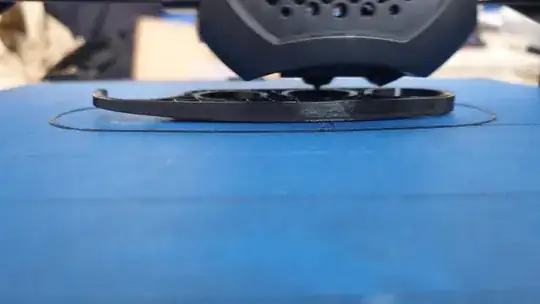

I've had all sorts of trouble getting first layer to stick but finally managed it. However the thin end of this hook has now warped and the other end is too.

Looking at the image above, you can see it's much thinner at that end. Should I try a lower nozzle temperature? Or bed? Or both?

The fans are at 50 % (set in Cura), should I have left them on 100 %?

I have to mention that the tape has been cleaned with isopropyl alcohol. I can print PLA no problem direct to the bed but am having so much trouble with PETG - rather than warping this could actually be adhesion problems. I've tried a higher initial layer (0.3 mm vs 0.2 mm), 0.1 mm Z offset, gapped to 1 sheet of paper as per PLA, then 2 sheets - I've done that 50 mm in on each corner and then checked it in the middle of the bed too. Initial layer is at 10 mm/s and then to 40 mm/s

As you can see in the picture the brim looks rather flattened, but if I give more gap (e.g. 3 sheets) it doesn't even stick at all.

I have managed to print a benchy after maybe 6 attempts, but this was luck and had really poor adhesion, a gentle tap with my finger dislodged it. The actual print was fine.

Tempted to try another PETG but wanted to make sure I'm not missing anything obvious - at the moment I can't even print the brim again because it won't stick.

I'm really confused because a lot of I read suggests PETG sticks really well but I've having the exact opposite experience.