I'm setting up my printer in a small room, and I thought I'd come up with a system for more easily swapping filaments, but I'm not yet sure it is feasible.

Rather than physically replace the spool, I'd like to hang most of my spools on the wall, where they can rotate, and only swap filament leads in the (direct drive) extruder. The spools would be placed at some distance from the extruder, and at various angles. So to make sure the filament is pulled from the spool at the proper angle, and to avoid breaking it, I think it should probably run through a flexible tube to reach the printer.

I know such tubes are used for Bowden style extruders, but what I'm proposing is different in at least two ways: [1] the extruder motor would be pulling (not pushing) filament through the tube and [2] the tube would be longer than normal, e.g., between 1 and 2 meters.

Is this plan feasible? Or are the problems I am not foreseeing?

Edit 1: I don't know where I got 1-2 meters from. The distance is actually closer to 50cm.

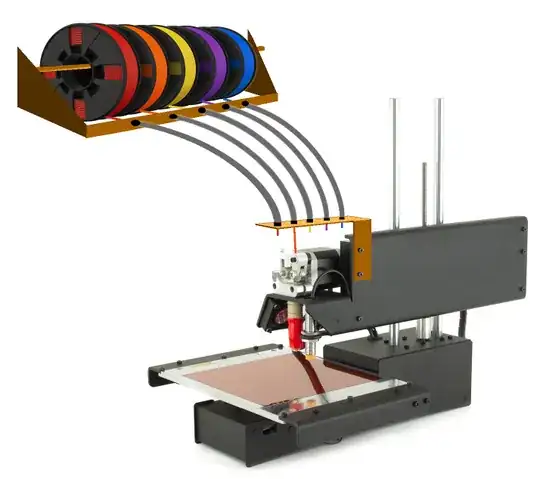

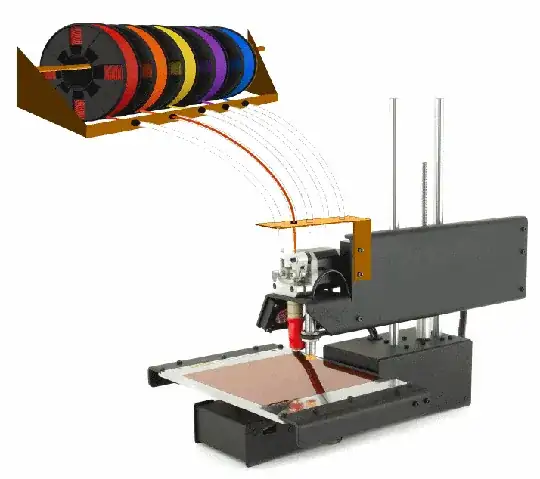

Edit 2: To clarify my proposed setup, here's a crude mockup: