We are using the Board SKR 1.3 with the following pins:

/**

* Trinamic Stallguard pins

*/

#define X_DIAG_PIN P1_29 // X-

#define Y_DIAG_PIN P1_27 // Y-

#define Z_DIAG_PIN P1_25 // Z-

#define E0_DIAG_PIN P1_28 // X+

#define E1_DIAG_PIN P1_26 // Y+

We need a double Z motor, so We have defined the number of stepper drivers to 2 and it works like a charm:

#define NUM_Z_STEPPER_DRIVERS 2

Here is the problem, We need to have a single extruder with two heating zones, not a real second extruder. We have defined the number of extruders to 2:

#define EXTRUDERS 2

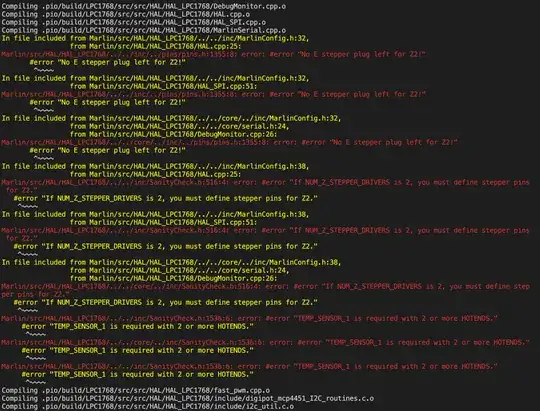

We want to reinforce that the second extruder does not exist, we only need the second heating zone. It's a big hotend with two different heating cartridges, that is, two different temperatures. So we do not need the stepper driver, only the temperature. Then we get the following error messages:

We have thought of enabling the chamber and use it's pin, but we got stuck with all the structure for it:

#define TEMP_SENSOR_CHAMBER 5

#define CHAMBER_MAXTEMP 250 // Extruder first temperature zone

#define HEATER_CHAMBER_PIN 24