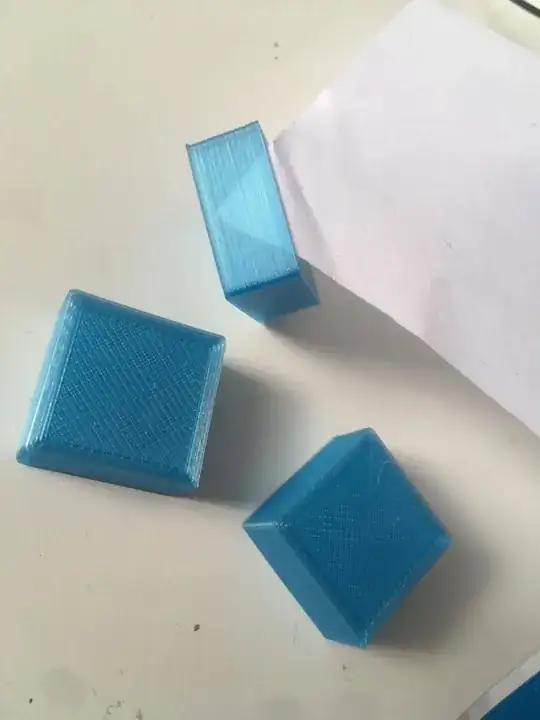

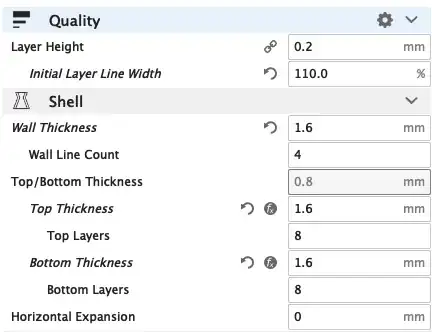

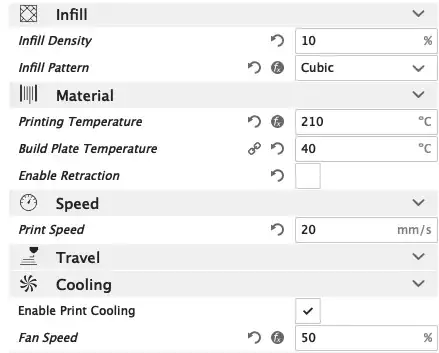

The print is very solid except for the 4 walls.

From the top, I can slide a paper down to the bottom. This is ONLY between the walls, the rest of the print is solid. The filament is PLA 1.75 mm.

But the bottom is solid, no gaps.

I have checked the usual problems on Ultimaker troubleshooting photo gallery, but I can find anything similar.

Any advice to fix this would be very welcome.