Here's my situation:

- PLA

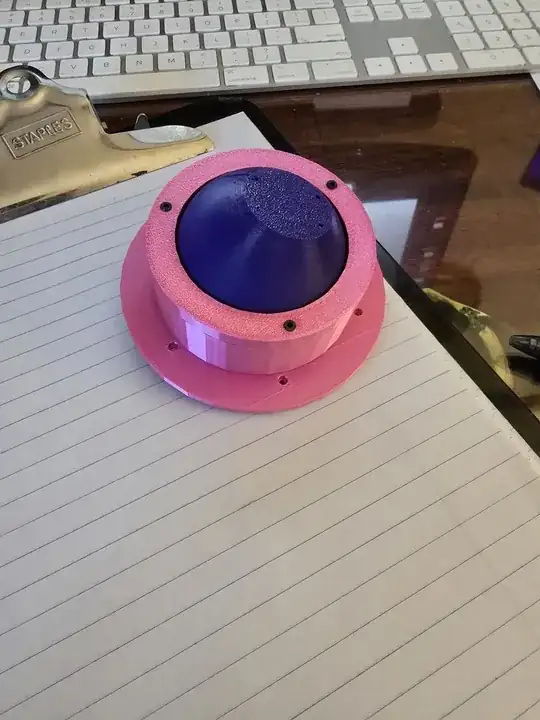

- I printed a 60 mm sphere.

- I printed a "holder" to hold the sphere where, on one end, I have a ton of 5 mm ball bearings in a channel providing somewhat smooth motion. On the back end, I will have 3 motors that will spin the sphere.

- The sphere moves freely, however, I wanted to do better, so I lubricated the ball bearings with silicone lubricant. That had a tremendously bad impact and made it much more difficult to rotate.

I'm looking for some suggestions on how to improve the smoothness. Is sanding my only option? Both the sphere itself and the channel where the ball bearings are held? I'm surprised silicone lubricant bombed so badly.