Qidi X-Max. PLA printing temp 200 °C build plate temp 60 °C.

I am using the back of the magnetic plate that came with the machine (the white front is a little worn out from ABS printing. the back is smooth and has worked pretty well. I am using Elmer's glue stick on the build plate.

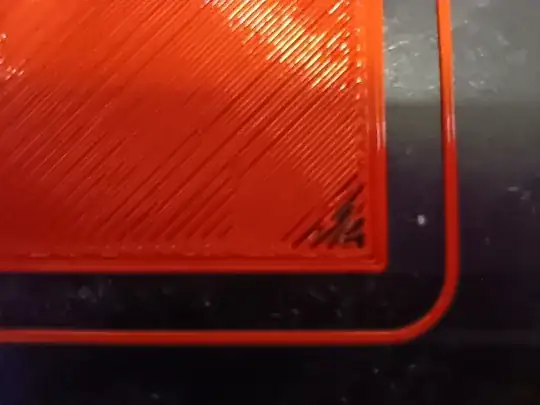

The first corner where the inside of the bottom layer is getting filled with diagonal lines leaves a void. The opposite diagonal corner, where the head is making short traverses is OK.

Not sure where to start. I can't find the "calibration sheet" that came with the printer to set extruder clearance, but a feeler gauge starts to show resistance around 0.55 mm to 0.60 mm.

Some relevant (?) speeds from the config panel:

- Print speed: 60 mm/s

- Wall speed: 30 mm/s

- Top/bottom speed (?): 30 mm/s

- Initial layer speed: 20 mm/s

I was able to minimize this by setting Enable Travel Prime, and I also reduced the initial gap to about 0.45 mm.

I will try to reduce the first layer speed from 20 mm/s to 15 mm/s and see if that also helps.