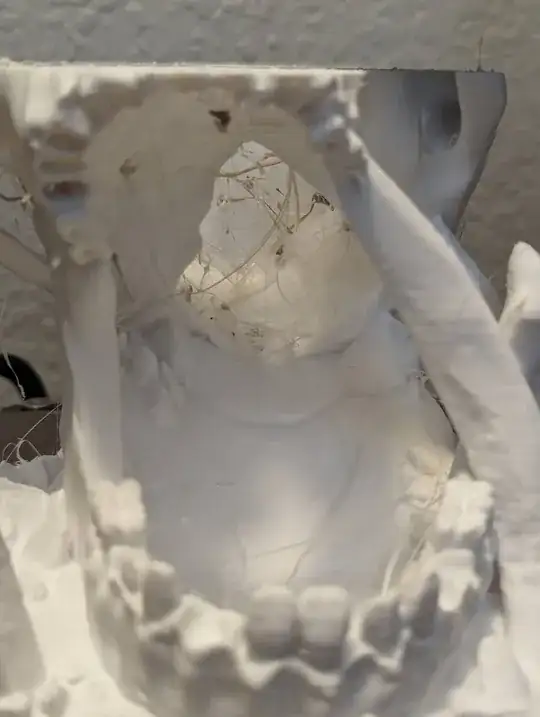

PETG really likes to stick to nozzles, especially when the nozzle moves over already-printed material in the same layer, which can pull it back up and drag it around or leave it stuck to the nozzle for a long time until it eventually comes off somewhere it shouldn't be, often blackened from spending a long time in contact with heat and air, or from getting mixed with carbonized gunk that was already on the outside of the nozzle.

Your picture shows grid infill, which is a prime suspect for the root cause. Grid, triangles, and cubic are all self-intersecting infill patterns where the nozzle crosses back over lines that have already been printed. At the intersection points, the slicer does not make any attempt to compensate for double extrusion, and in fact there really isn't any good physical way to compensate without some fancy Z motion or stopping and starting that would be prohibitively slow on most printers.

Non-self-intersecting infill patterns like gyroid (any modern slicer) or full honeycomb (PrusaSlicer & derivatives) should go a long way to mitigate this problem.

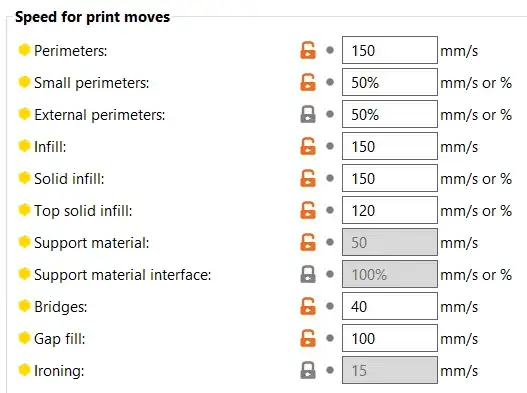

Some users also find higher temperatures and/or lower infill speeds solve the problem by giving the needed time/heat to cleanly melt through the original extrusion line when crossing it the second time.