This is my first 3D printer so I'm not entirely sure what could be the cause of this issue.

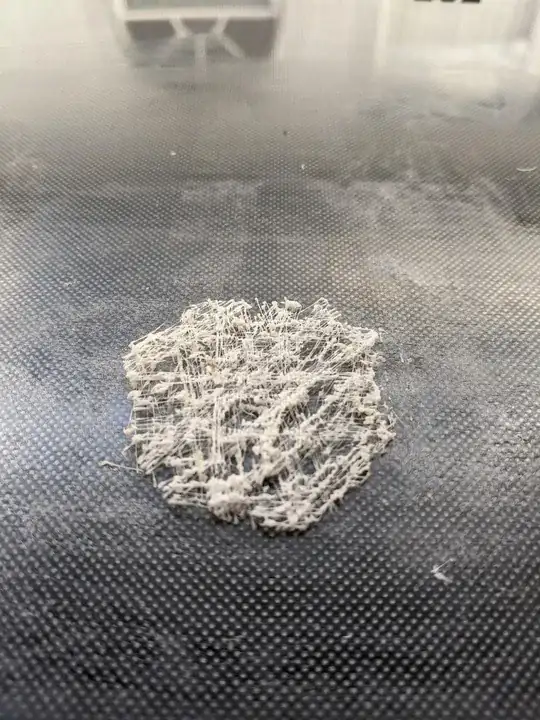

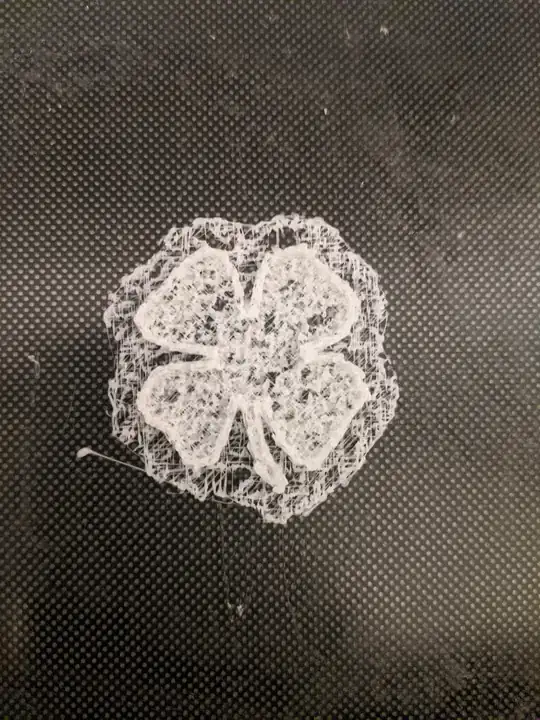

I recently got a SUNLU S8 3D printer and have been trying to print the first test file, however, the layers end up stringy (for lack of a better word -- if anyone knows whether this is called something else, I'd appreciate the knowledge because Google searching for stringy layers does not yield similar results).

Anyway, I tried to increase the nozzle temperature from 205 °C to 215 °C and that seems to help slightly (filament is PLA and came with the printer). I also noticed that the extruder's feeder gear is grinding on the filament so I suspect that may be part of the problem.

Before I purchase an extruder kit, I figured I'd reach out and ask this community what they think could be the problem.

Does anyone know what might be causing this issue?

Edit

I cleaned the tubing and nozzle, and then releveled the bed. The filament was still stringy and whispy, however, I decided to let it print for a while. Although the picture is a top-down view, the walls of the print are also holey.